Flexitallic is the market leader in the manufacturing and supply of static sealing solutions

Hydrogen

Technologies and systems for producing, transporting, storing, and using hydrogen and its products (such as ammonia, liquid organic carriers, synthetic fuels) demand high grade sealing materials and gasket designs.

Solar Power

Using hotter heat transfer media requires developers to convert from traditional graphite-based sealing to a new generation of advanced materials from Flexitallic.

Fuel Cells (SOFC)

Flexitallic’s Thermiculite® 866 has been accepted industry-wide as the sealing material for a wide range of SOFC seals, including automotive and auxiliary power units.

Nuclear

Flange failure is not an option. We know that. Nuclear Power demands a higher level of performance from both gaskets—and the people who install them. We help with both.

agrichemical

Few gaskets can handle the complex environment present in ammonia/nitric acid production. So, if you haven’t already made the switch to the Change™ gasket—designed to deliver a seal with the most dynamic recovery in the industry—it’s time.

Power Generation

Our methods of preventing oxidation and galvanic corrosion gain steam daily in plants around the globe.

Chemical Processing

Being able to confidently seal your process line gives you the freedom to develop new chemistries for bold applications—safely.

Refining

Our product versatility and material innovation have served this group well with sealing solutions that outperform in the extremes of temperature and pressure.

Petrochemical

With petrochemicals, fire-safety is the bottom line. But Flexitallic considers the industry’s opportunities as well. With each bringing a demand for increased pressure and/or temperature resilience. You can innovate with confidence. Because standing still isn’t safe either.

Oil & Gas

The challenges faced by organizations working in the upstream oil and gas industry depend on the location of the crude oil and natural gas.

Ethylene

The oxidising environment of ethylene production represents a big challenge for sealing materials. Superheated steam and external air, in combination with the high temperatures, create oxidising conditions even for high specification, oxidation inhibited, grades of graphite.

FCCU & Hydrocracking

Cracking processes within a refinery are critical to their operation and present additional challenges due to their high operating temperature. Two key technologies in use are fluid catalytic cracking (FCC) and hydrocracking. Although their process chemistry differs, they both present demands with high temperatures, gasket oxidation risk and equipment with custom flanges which require bespoke gaskets.

Fertilizer

You’ll already know how demanding the service environment is across your plant during ammonia and nitric acid production.

Extreme temperatures, thermal cycling and highly oxidising environments put added pressure on sealing materials, some of which simply cannot withstand the demands placed on them.

Marine

Our materials maintain their integrity despite the requirements of marine catalytic exhaust systems. And by matching materials, we can reduce low-sulfur emissions and avoid potential fines.

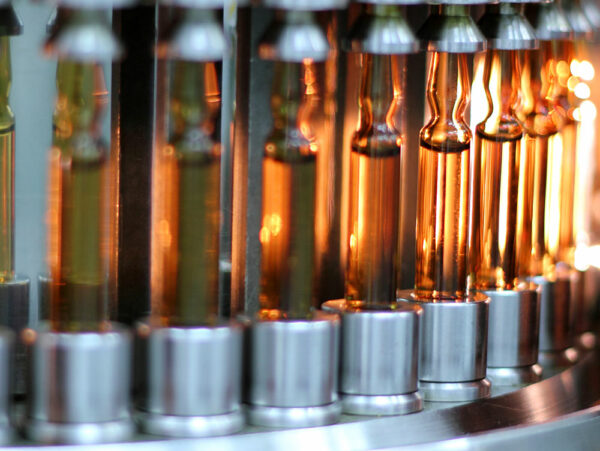

Pharmaceutical

Undetected leaks can jeopardize health. The solution is our Sigma® PTFE gaskets, suitable for all media and flange types—it’s a reliable, secure seal that requires minimum assembly stress.

Food & Beverage

Flexitallic Flexidram™ is a hybrid gasket that augments fire safety and cleanliness. Flexidram supports pipeline integrity, decreased emissions, and eliminates contamination.

Aerospace

We thought that we should make a gasket that will resist g-forces, ultra-extremes in temperature and pressure—and last 60% longer than anything else. It’s called the Change™ gasket. It’s taken off.

OEM

Flexitallic engineers can also advise on your design plans and create custom sealing solutions that will keep you, your people, and your good name nice and shiny.