Gaskets for the Fertilizer Industry

NITROGEN BASED FERTILIZER APPLICATIONS

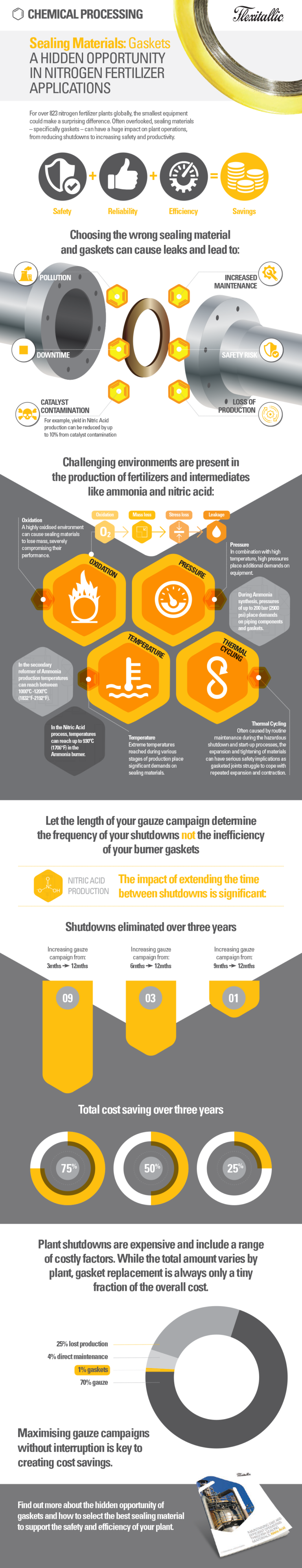

Approximately 55 million t/year of nitric acid are produced globally with projections of further growth over the next 5 years. At the same time, meeting global environmental standards by reducing nitrous oxide emissions, is a key consideration, alongside improving plant efficiency and reducing costs. Balancing these factors, while maintaining safety standards at all costs, dictates that all equipment must perform at its best.

There are a variety of hotspots within the nitric acid production process that can negatively affect sealing materials. Extreme temperatures, thermal cycling and highly oxidising environments put added pressure on sealing materials, some of which simply cannot withstand the demands placed on them. This leads to gasket failure and leaks, ultimately costing your plant money for unplanned shutdowns and costly maintenance operations.

AMMONIA

Over 180 million mtpa of ammonia is produced globally, with approximately 80% used in the production of fertilizers. With such high production volumes to maintain, it’s crucial plants operate as efficiently as possible, minimizing unplanned downtime and optimising equipment as much as possible.

You’ll already know how demanding the service environment is across your plant during ammonia production. But do you know where your gaskets are under the most strain and where you could achieve efficiencies by choosing the right sealing material and gasket type? Gaskets made from unsuitable sealing materials for their environment will degrade prematurely and cause leaks, which, in many cases, require unplanned shutdowns for costly and complex maintenance operations.

Featured products for Fertilizer

Download Whitepapers for Ammonia and Nitric Acid

As a seasoned Sealing Applications Engineer some of our most demanding sealing challenges often involve Aggressive chemicals. Coming up with the best solution can require an appreciation of not just the application conditions; temperature, pressure and media but the subtle interplay of all three with regard to the most appropriate gasket design.

- Dene Halkyard, Technical Director, Flexitallic UK Ltd