Reliable sealing solutions for the Aerospace industry.

In the aerospace industry joints and seals are tested to their limits. There’s the severe stress from g-forces on take-off, landing and manoeuvers, while temperatures and pressure changes are extreme and rapid during ascent and descent.

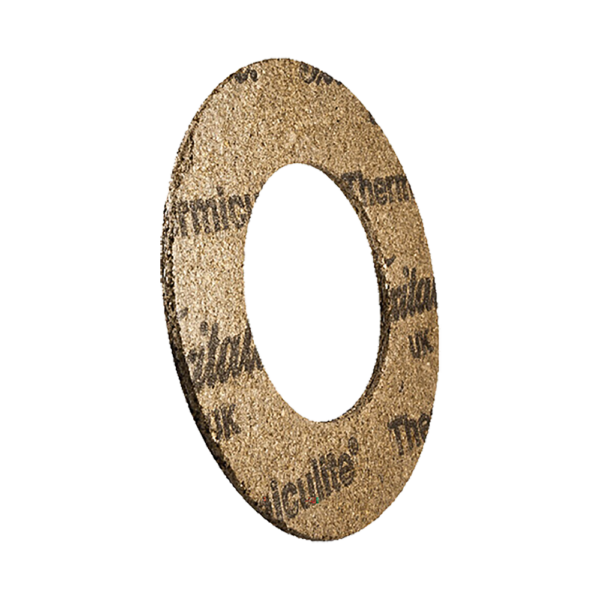

Our involvement in aerospace began with the Apollo Space Programme, which relied on our revolutionary high temperature sealing material, Thermiculite®. Over the decades we’ve continued to innovate, creating new sealing technologies that are resilient and effective in the most challenging environments.

The changes in temperature aircrafts experience during flight, cause gaskets to expand and contract, which over time can lead to gasket fatigue. To overcome this issue we developed the Change® gasket. Highly resistant to temperature change, it’s been proven to last 60% longer than traditional sealing technology, which has huge benefits for the aerospace industry.

For added security, our fire-safe sealing materials meet industry approved standards and are supplied with detailed and comprehensive audit reports, material certification and traceability.

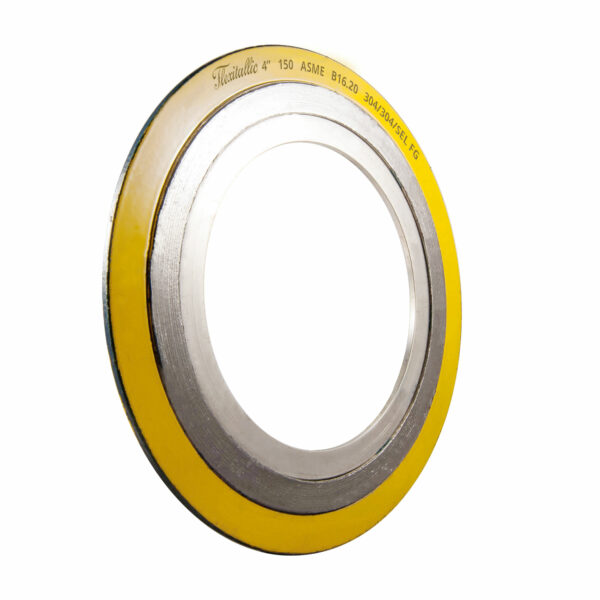

Featured products for Aerospace

Download our Aerospace brochure

When it comes to the aerospace industry you can’t leave anything to chance. You need to know that the gaskets and sealing materials you’re using are fit for purpose, reliable and durable. At Flexitallic we offer in-process first off, last off testing and provide a comprehensive audit trail from raw material to finished product.

- Giang Dang, Applications Engineer, Flexitallic US LLC