Introducing the FLEX SL™, a proprietary design for long-haul reliability without flange welding or misalignment.

These gaskets conform to standard DIN, ANSI, JIS, and BS flanges normally installed in pipelines. The most important feature of the gasket is the high unit load generated by the narrow sealing area provides a considerably higher flange clamping pressure and a better seal at a lower clamping force.

*Flexitallic can manufacture custom metal carriers and sealing materials for your application.

KEY BENEFITS

- Ability to cope against severe thermal cycling and vibration

- Inherent Live Loading capability

- Fire, Blow Out, & Leak proof

- Superior pressure handling

- Universal one gasket for all pressure classes – ANSI 150# – 2500#

- Protects against use of the wrong gasket

- Lowers total sealing costs

- Cannot be over compressed

- No need to re-torque

- Eliminates fugitive emissions

- ANSI, DIN, JIS, BS and AUS sizes available

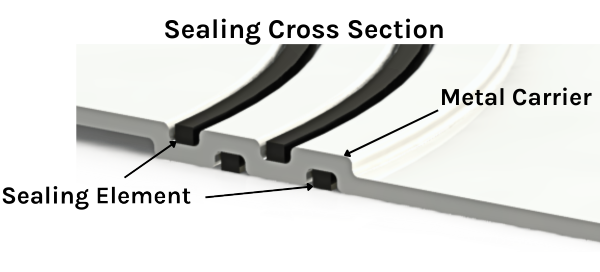

Cross Section Design

The standard gasket material is 304 SS, with two (2) tracks of SEL+ Flexible Graphite sealing elements. Specialty gasket material and/or sealing elements are available as options.

Innovation to Application

TECHNICAL DATA

Sizes: ½, ¾, 1, 1¼, 1½, 2, 2½ (including metric equivalent) 3, 3½, 4, 5, 6, 8, 10, 12 14, 16, 18, 20, 22, 24

Flange Pressure Class: 150# to 2500#

Thickness: 1/16″ (1.6mm). Other thicknesses available, contact engineering department for more details

Torque Values: 50% to 65% of Bolt Yield†

Flange Surface Finish: 10 to 400 µin RMS

(micro inches)

Sealing Track Width:

- ½ to 1¼ (gasket size) 0.100″ each side.

- ≥1½ (gasket size) 0.125″ each side.

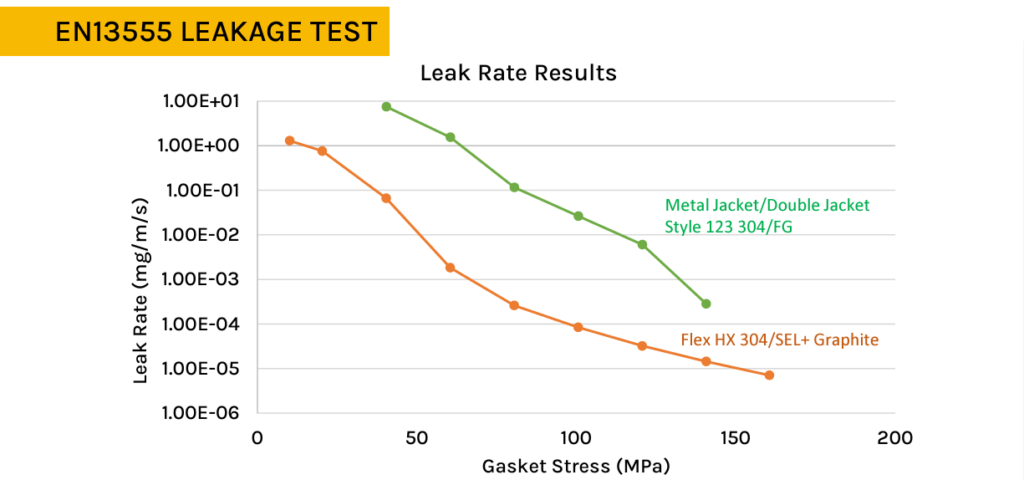

Leak Rate: 0.005 in mg/m ∙ s (DIN 28090 / 1..2) < 10ppm @ He

Temperature Range: -328°F/-200°C cryogenic air +932°F/+500°C in regular atmosphere + 1202°F/+650°C in steam +1832°F/+1000°C reducing or inert media. Varies by material.

Pressure Range: Full vacuum to +5000 psi

Minimum Seating Stress: 2900 psi (20 MPa)

Maximum Seating Stress: 23,200 psi

(160 MPa) (testing equipment limit)

Recommended Seating Stress: 5800 to 8700 psi (40 to 60 MPa)

Available Sizes for Flange Standards:

ANSI 16.5, DIN 2600, JIS B2220, BS 4505, BS 10, AUS 2129

METAL CARRIER OPTIONS

- Carbon Steel

- MONEL®

- INCONEL®

- Copper

- AL6XN®(Stainless Steel)

- 304 Stainless Steel

- 316 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- HASTELLOY®

- NickelTitanium

SEALING ELEMENT OPTIONS

- SEL+ Flexible Graphite

- PTFE

- Thermiculite®

- Corriculite™