Now there’s a Manway Gasket that ends fugitive emissions, damaged gasket surfaces, and gasket blowouts, introducing the FLEX MW™.

The ability to be used in a wide range of surface finishes and operating pressures, and a gasket which is designed to stay in place during closing.

Eliminate problems with leakage, gasket surface damage, gasket blow out, damage to other equipment and/or personnel. The most important feature of the gasket is the high unit load generated by the narrow sealing area provides a considerably higher flange clamping pressure and a better seal at a lower clamping force.

*Flexitallic can manufacture custom metal carriers and sealing materials for your application.

KEY BENEFITS

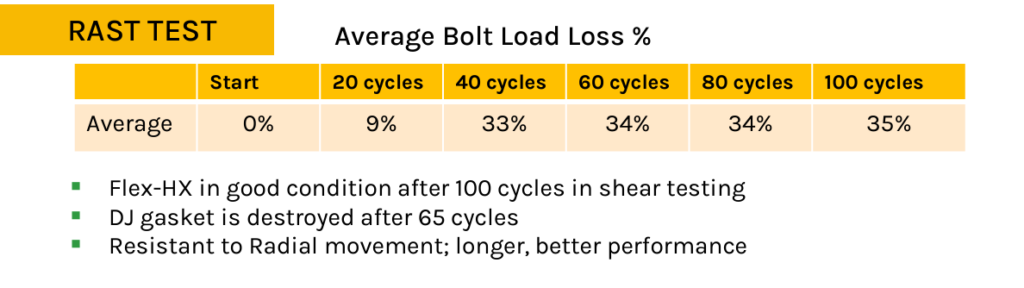

- Ability to cope against severe thermal cycling and vibration

- Inherent Live Loading capability

- Fire, Blow Out, & Leak proof

- Superior pressure handling

- Ease of installation Lower seating load

- Cannot be over-compressed

- No need to re-torque

- Eliminates fugitive emissions

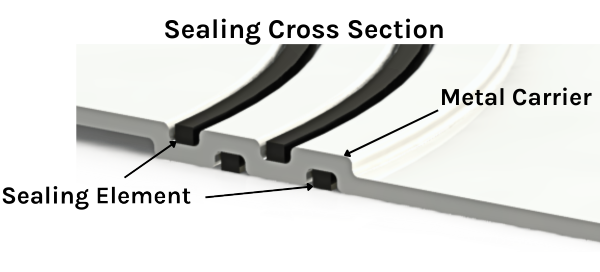

Cross Section Design

The metal gasket material with two (2) tracks of SEL + Flexible Graphite sealing elements. Specialty gasket material and/or sealing elements are available as options.

Innovation to Application

TECHNICAL DATA

Sizes: 12 x 16, 14 x 18, 16 x 18, 18 x 24, 20 x 24, 22 x 26

Thickness: 1/16″ (1.6mm) Other thicknesses available, contact engineering department for more details

Surface Finish: 10 to 400 µin RMS

(microinches)

Sealing Track width: 0.125″ each side

Minimal sealing track web width: 0.375″

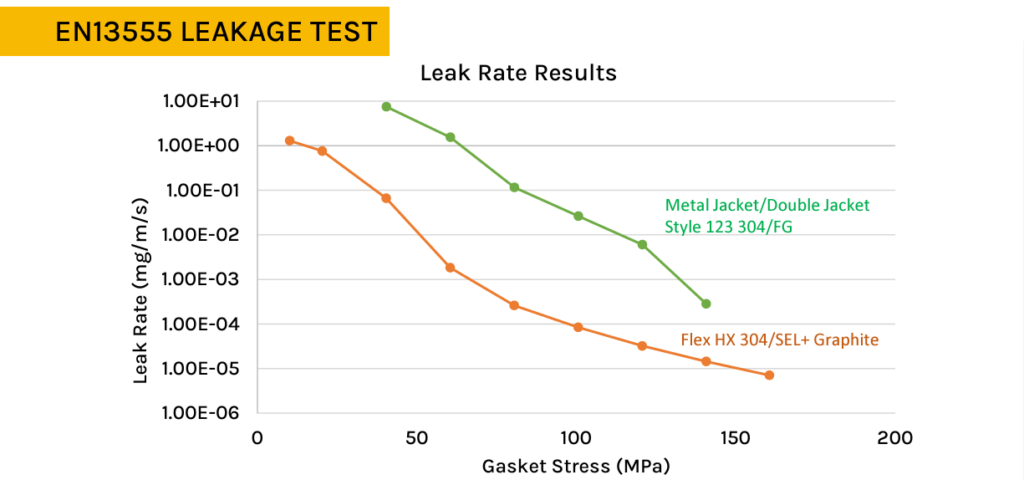

Leak Rate: 0.005 in mg/m ∙ s (DIN 28090 / 1..2) < 10ppm @ He

Temperature Range: -328°F/-200°C cryogenic air +932°F/+500°C in regular atmosphere + 1202°F/+650°C in steam +1832°F/+1000°C reducing or inert media. Varies by material.

Pressure Range: Full vacuum to +5000 psi

Minimum Seating Stress: 2900 psi (20 MPa)

Maximum Seating Stress: 23,200 psi (160 MPa) (testing equipment limit)

Recommended Seating Stress: 5800

to 8700 psi (40 to 60 MPa)

METAL CARRIER OPTIONS

- Carbon Steel

- MONEL®

- INCONEL®

- Copper

- AL6XN®(Stainless Steel)

- 304 Stainless Steel

- 316 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- HASTELLOY®

- NickelTitanium

SEALING ELEMENT OPTIONS

- SEL+ Flexible Graphite

- PTFE

- Thermiculite®

- Corriculite™