Sealing solutions for Hydrogen Service

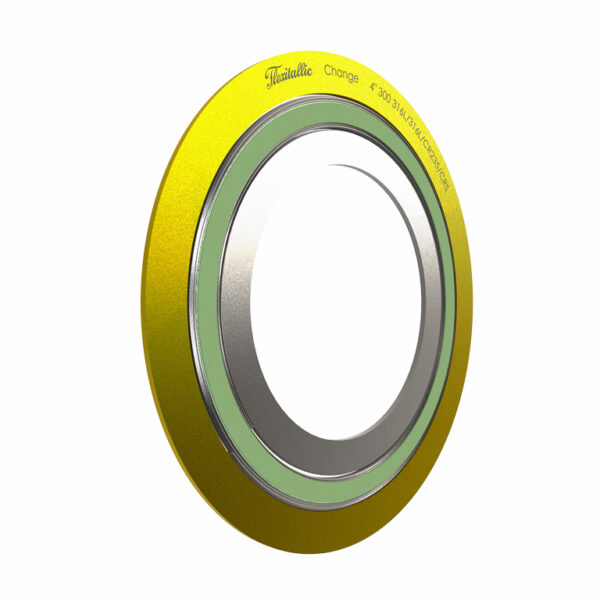

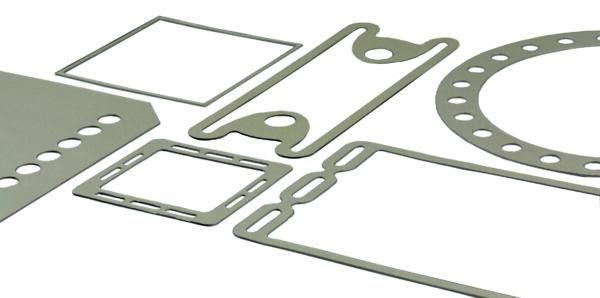

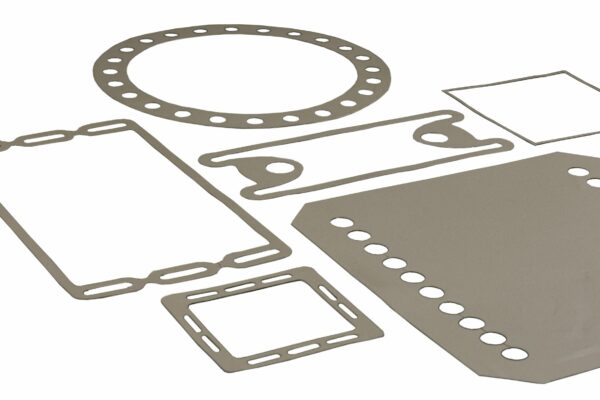

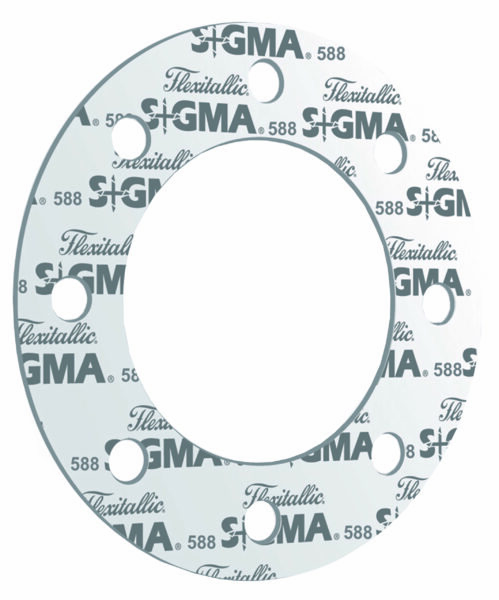

Whether it is grey, blue, or green hydrogen, Flexitallic has the expertise and product’s for your hydrogen applications. Technologies and systems for producing, transporting, storing, and using hydrogen and its products (such as ammonia, liquid organic carriers, synthetic fuels) demand high grade sealing materials and gasket designs.

Sealing hydrogen presents two major challenges due to its unique properties. Hydrogen is a very small molecule, meaning that gasket materials must have tight internal structures and good ability to conform to mating flanges. Second, it is highly flammable, and explosive so extremely reliable sealing is needed.

Most of today’s hydrogen is produced using well established technologies such as steam methane reforming (SMR) and is consumed in three key industries – oil refining, ammonia production and methanol synthesis. Flexitallic has a wealth of experience in this sector with proven products. However as new technologies are being developed and commercialised, improved sealing technologies, such as Corriculite® are required.

Through our expertise built up over two decades in high temperature fuel cell and electrolyser technology (solid oxide and molten carbonate) we are ideally placed to help you navigate the energy transition.

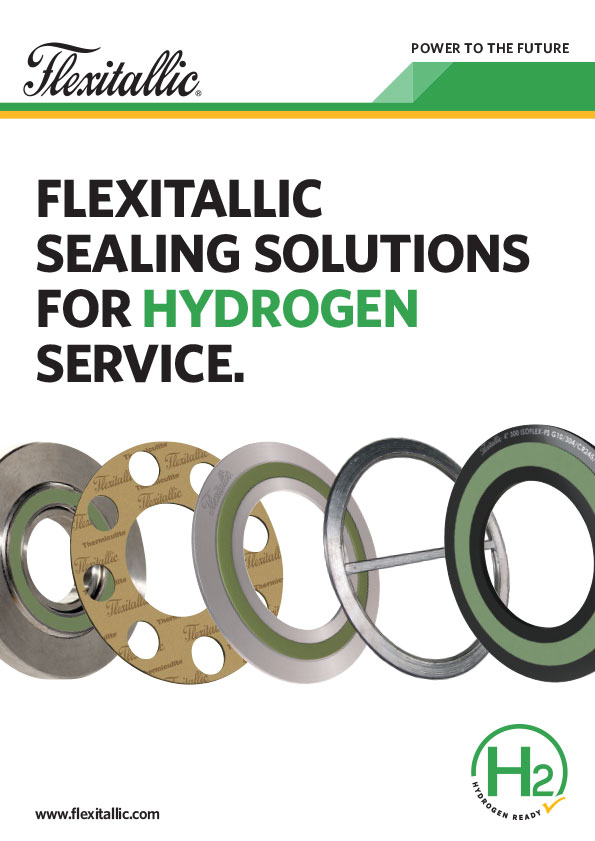

Featured products for Hydrogen

Over the years, we’ve continued to push the boundaries of sealing technology. Always with a focus on quality, we’ve created increasingly advanced engineered sealing solutions that demonstrate consistently high performance under extreme conditions. It’s our drive for innovation combined with our focus on quality and control, which allows us to meet the exacting demands of the nuclear industry, by providing nuclear approved sealing products.

- Richard Rodgers, Applications Engineer, Flexitallic UK Ltd