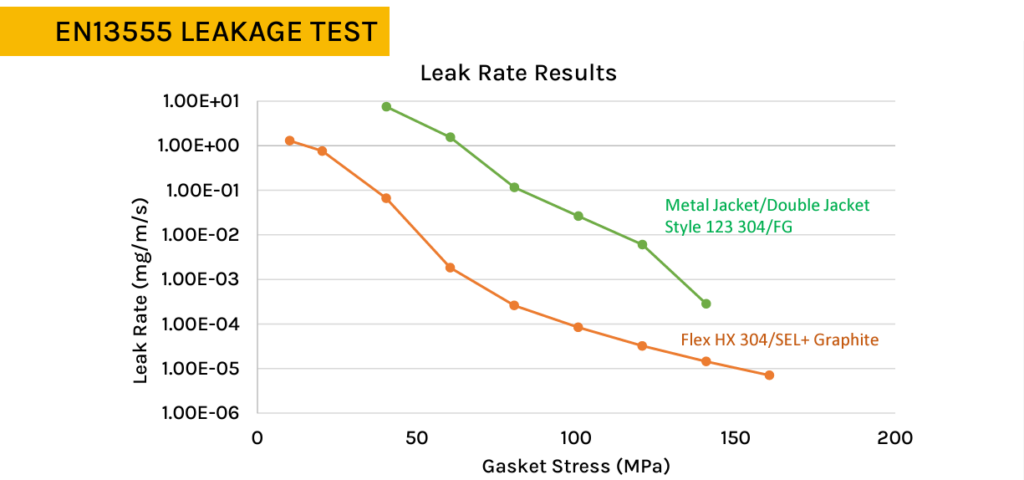

Unlike leaky Double Jacketed gaskets, The FLEX HX is a cost-effective sealing solution designed to handle flange movements, vibrations, and a tighter seal that will not leak in Heat Exchanger applications.

Our reengineered FLEX Heat Exchanger gasket creates a high unit load that is generated by the narrow sealing area. This provides more flange clamping pressure and a better seal with less compression. It can’t be over-torqued. FLEX HX can be made in almost any shape or configuration.

*Flexitallic can manufacture custom metal carriers and sealing materials for your application.

KEY BENEFITS

- Ability to cope against severe thermal cycling and vibration

- Inherent Live Loading capability

- Fire, Blow Out, & Leak proof

- Superior pressure handling

- Ease of installation Lower seating load

- Cannot be over-compressed

- No need to re-torque

- Eliminates fugitive emissions

Cross Section Design

The metal gasket material with two (2) tracks of SEL + Flexible Graphite sealing elements. Specialty gasket material and/or sealing elements are available as options.

Leak-free Corrugated Metal Gaskets for Heat Exchangers, Manways, and Pipe Flanges. Gaskets are engineered to install easily, end emissions, and create a more effective seal with less compression.

Innovation to Application

TECHNICAL DATA

Flange Pressure Class: 150# to 2500#

Thickness: 1/16″ (1.6mm) Other thicknesses available, contact engineering department for more details

Flange Surface Finish: 10 to 400 μin RMS (microinches)

Sealing Track Width:

• ½ to 1¼ (gasket size)0.100″ each side.

• ≥1½ (gasket size) 0.125″ each side.

Minimal Sealing Track Web Width: 0.670“

Leak Rate: 0.005 in mg/m ∙s (DIN 28090 / 1..2) < 10ppm @ He

Temperature Range: -328°F/-200°C cryogenic air +932°F/+500°C in regular atmosphere + 1202°F/+650°C in steam +1832°F/+1000°C reducing or inert media. Varies by material.

Pressure Range: Full vacuum to +5000 psi

Minimum Seating Stress: 2900 psi (20 MPa)

Maximum Seating Stress: 23,200 psi (160 MPa) (testing equipment limit)

Recommended Seating Stress: 5800 to 8700 psi (40 to 60 MPa)

Available Sizes for Flange Standards:

ANSI 16.5, DIN 2600, JIS B2220, BS 4505, BS 10, AUS 2129

METAL CARRIER OPTIONS

- Carbon Steel

- MONEL®

- INCONEL®

- Copper

- AL6XN®(Stainless Steel)

- 304 Stainless Steel

- 316 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- HASTELLOY®

- Nickel

- Titanium

SEALING ELEMENT OPTIONS

- SEL+ Flexible Graphite

- PTFE

- Thermiculite®

- Corriculite™