Gaskets for Fluid Catalytic Cracking Units (FCCU) and Hydrocracking

The increase in fuel standards, operational efficiency and stress on green resources is expected to contribute to the increase in fluid catalytic cracking requirements. This demand to increase yield requires an increase in temperature putting pressure on the performance of any sealing materials and potentially compromising safety.

Temperature

Operating temperatures over 500°C (932°F), place sealing materials under significant strain and often leads to gasket failure.

Thermal cycling

Often caused by routine shutdowns, rapid temperature changes cause repeated expansion and contraction, putting unmanageable stress on gasketed joints

Degradation

Gaskets contain a series of bonds holding the structure of the material together. The bonds lose their adhesion as the temperature reaches the material limits, resulting in gasket failure.

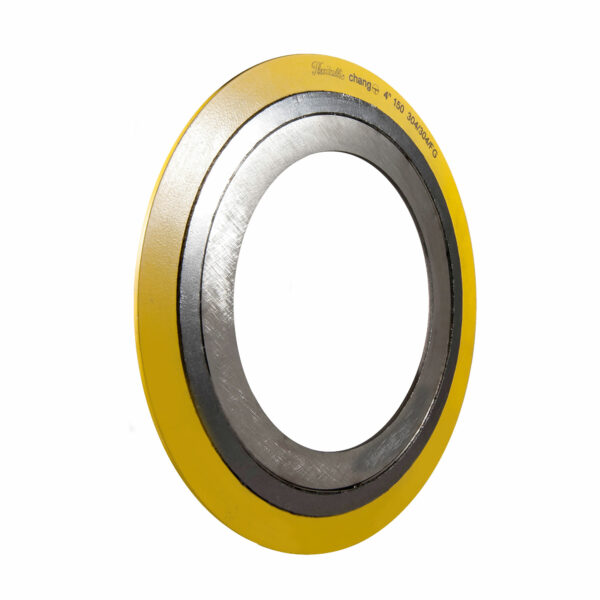

Featured products for FCCU & Hydrocracking

Download our FCCU & Hydrocracking whitepaper

As a seasoned Sealing Applications Engineer some of our most demanding sealing challenges often involve Aggressive chemicals. Coming up with the best solution can require an appreciation of not just the application conditions; temperature, pressure and media but the subtle interplay of all three with regard to the most appropriate gasket design.

- Dene Halkyard, Technical Director, Flexitallic UK Ltd