Safer sealing solutions in Chemical Processing

Different chemical processing operations cause different problems. When it comes to sealing solutions, aggressive chemicals, high pressures and extreme temperatures can all create challenging conditions. Chemical compatibility is a particularly important consideration. Use Using incompatible materials and the seal may prematurely degrade the seal, putting the safety of your site and people in jeopardy.

As with all bolted connections, appropriate gasket selection is only one of many considerations if joint integrity is to be achieved. In safety critical applications Flexitallic takes a holistic view of the connection ensuring that other mechanical components, i.e. fasteners and flanges, are appropriately matched.

Installation advice may include assembly stress guidance ensuring that all other mechanical components in the connection are appropriately stressed resulting in a leak free joint.

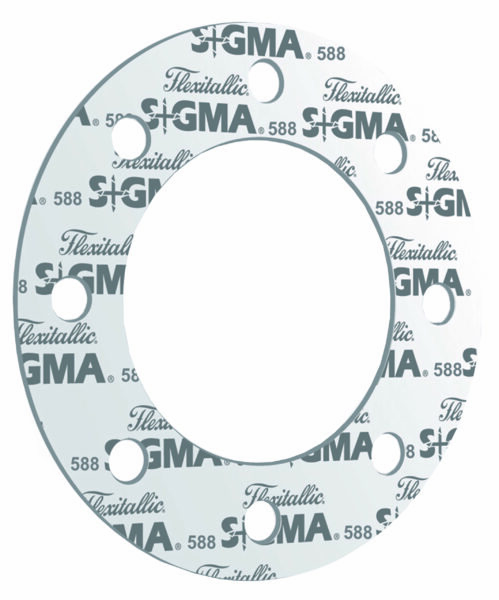

Chemical processing operations often rely on traditional PTFE gaskets which tend to creep over time, resulting in seal failure. To overcome this issue, we developed Sigma®. Offering compatibility with virtually all chemical media, Sigma® remains stable even at high temperatures and pressures. It’s also inherently clean, EC1935 certified and FDA approved, making it ideal for use in the chemical processing industry.

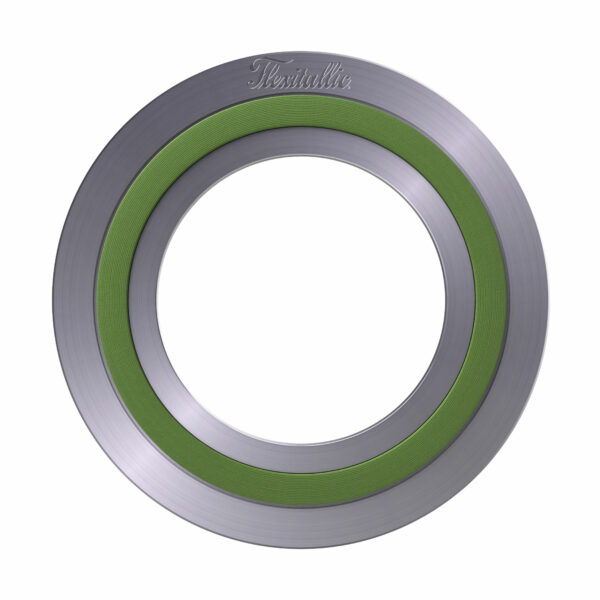

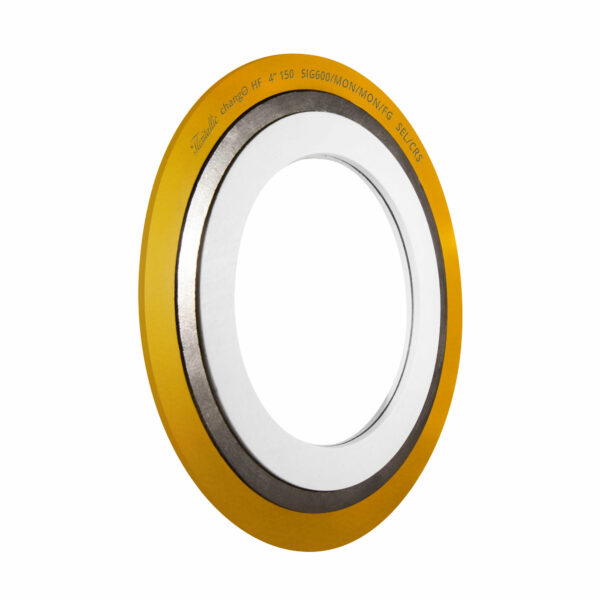

Featured products for Chemical Processing

Download our Chemical Processing brochure

Gaskets are a safety critical component within any manufacturing process. If a seal fails, leaks occur and production stops. That costs a company financially and can cause reputational damage, not to mention the potential health and safety risks to people and the environment. That’s why we don’t just supply gaskets, we understand your needs, and advise on the most effective sealing solution available.

- Russ Currie, Director of Engineering and Technology, Flexitallic Canada