Safer sealing solutions for High Pressure Environments

When you’re working in high pressure environments, whether it’s those found in subsea applications, or resulting from sealing highly pressurised gases or liquids, you need to be confident that the seal is fit for purpose. After all, the consequences of a seal ‘blowing out’ under pressure can be catastrophic.

What is considered to be high pressure will depend on the industry or application. For example in oil and gas exploration pressures can reach 1034bar (15,000psi), whereas in a nitric acid ammonia burner high pressure might be 10 bar (145psi). Irrespective of the absolute level, materials behave differently and this can be further complicated by fluctuating pressures and temperatures, aggressive chemicals, galvanic corrosion and difficult working environments.

We have more than a century of experience in creating gaskets that remain resilient even in the most demanding environments. Over the years, we’ve created a range of tried and tested, high pressure gaskets designed to keep your colleagues, the environment and your organisation’s reputation safe and secure.

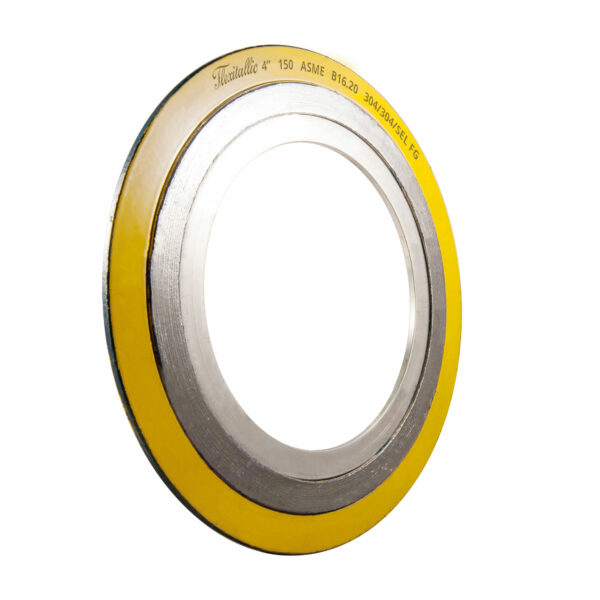

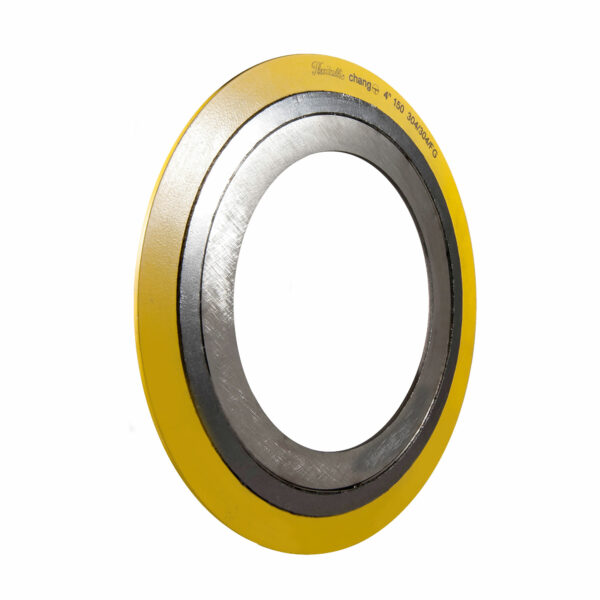

Featured products for High Pressure

Download our High Pressure brochure

The correct product depends on the application. For low pressure classes our PTFE sheet gaskets might be most appropriate. Above Class 300 however, you’re looking at metal ring type joints (RTJs). Our RTJs are manufactured to meet API 6A and ASME B6.20 sizes and ratings, and come in a range of alloys and coatings to suit different applications.

- Alex Lattimer, Director of Strategic Sales and Marketing