Working safely at extremely low temperatures

Gaskets sealing in cryogenic service, need to function at extremely low temperatures. When dealing with certain media, for example liquid natural gas (LNG), the seal must perform consistently at temperatures below -160oC At such low temperatures, some materials such as carbon steel and certain elastomers become too brittle to work effectively.

Another consideration is the seal’s resilience to cyclic loading. Depending on the application seals can be faced with sudden temperature fluctuations. Under such conditions the gasket must be able to react to sudden changes in cyclic stress. An important part of overcoming these challenges is to take a holistic view of the bolted connection. Matching the metallurgy of the flange, bolts and gasket helps to mitigate differences in the thermal expansion of the individual components that make up the seal.

Taking the above challenges into account and following extensive research, Flexitallic have created high performance sealing solutions for use in a wide range of cryogenic sealing applications, such as LNG, Liquid Oxygen Service and Liquid Nitrogen etc.

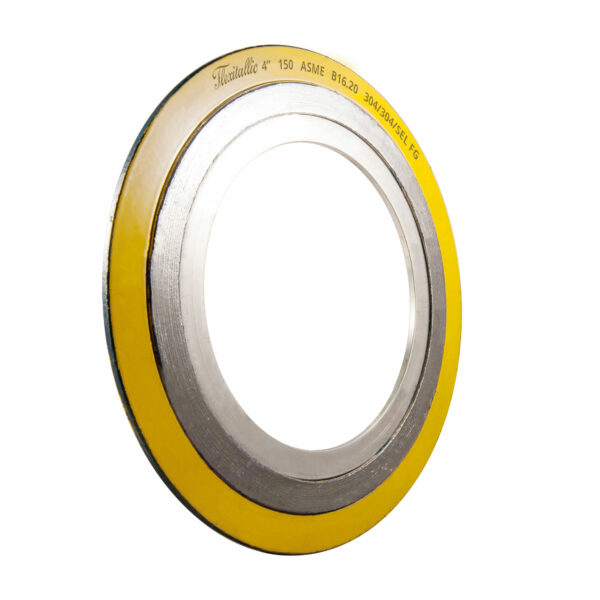

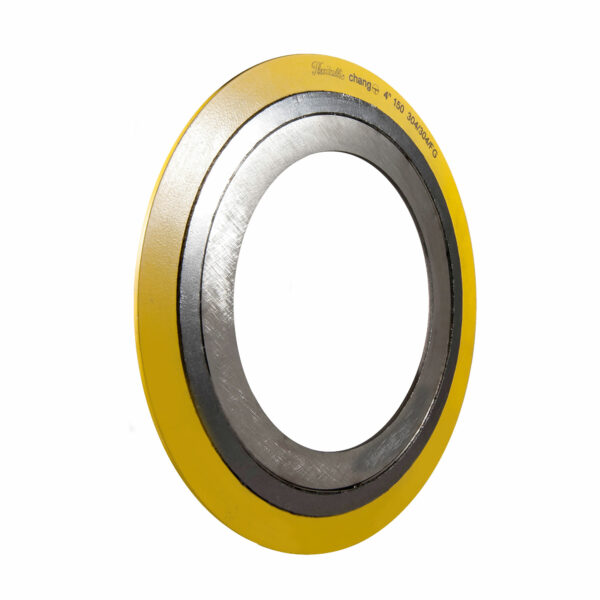

Featured products for Cryogenic

Download our Cryogenic brochure

Cryogenic applications, are common across many industries, including chemical, pharmaceutical and petroleum industries and bring their own set of challenges. There are also pressure and chemical issues to take into consideration. Our experts will look at your specific requirements and advise on the most appropriate product for your cryogenic needs. ‘Change’ gasket technology optimises seal resilience giving rise to outstanding sealing performance in cyclic cryogenic service

- Vinay Tripurana, Applications Engineering Manager, Flexitallic UK Ltd