We turn our innovations into applications for preventing oxidation.

Oxidation is a concern in all graphite gaskets, particularly when using graphite as a spiral wound filler material or a kammprofile facing. Oxidation converts the graphite to carbon monoxide and carbon dioxide, leaving microscopic voids in the material that, over time, will create a leak path.

Oxidation can be chemical or thermal, and can start from the inside or the outside of the sealing element. Chemical oxidation occurs when chemicals which are oxidising agents come into contact with the gasket, and therefore react with the graphite. Thermal oxidation occurs at high temperatures where oxygen within the process fluid reacts with the inner portion of the seal, or oxygen present in ambient air reacts with the outside of the joint. The rate of oxidation is highly dependent on temperature. Both situations can degrade the gasket and cause seal failure.

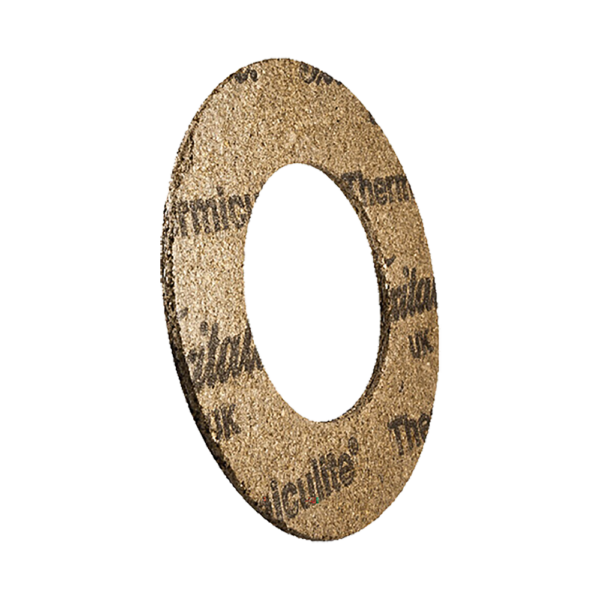

While sometimes the focus is on graphite purity, this alone is not enough to prevent oxidation at high temperatures. Graphite of any purity, even 100% pure graphite will begin to oxidize around 350°C/662°F and the rate will accelerate as temperature increases. In order to slow the rate of oxidation, the graphite material must contain chemical oxidation inhibitors, such as phosphates. We do not recommend the use of non-inhibited graphite for any application, and we do not recommend graphite for any application above 450°C/842°F. For very high temperatures, it is necessary to employ materials that are not prone to oxidation such as vermiculite.

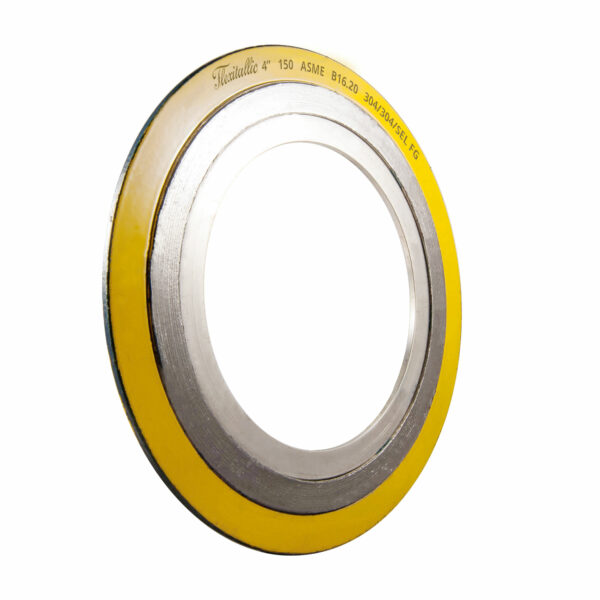

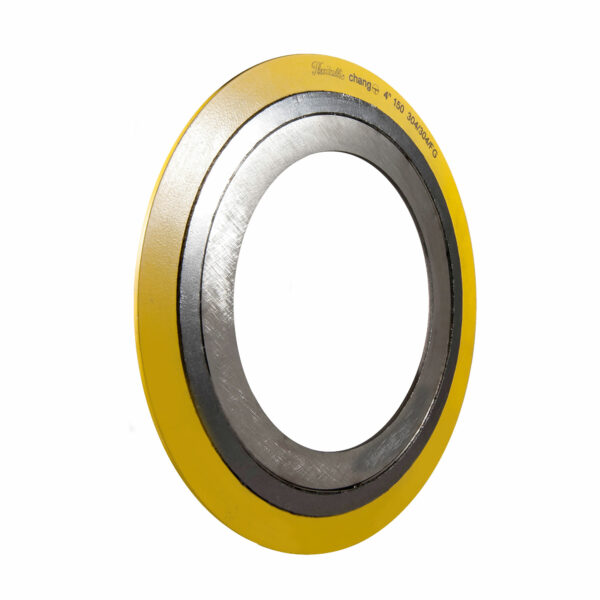

Featured products for Preventing Oxidation

Download our Preventing Oxidation brochure

Industry awareness and focus on graphite quality has increased substantially over the past five years. A significant amount of research and testing has been done to determine the performance of different graphite materials. Flexitallic is on the leading edge of this work, offering high quality inhibited graphite in our standard gaskets in the USA, and available globally. And for highly oxidative conditions we offer our unique Thermiculite material which has zero oxidation for the longest lasting seal.

- Stephen Bond, VP of Research and Development, Flexitallic Group