Introducing: Sigma® ONE

HIGH PERFORMING BIAXIALLY ORIENTATED PTFE WITH A PROPRIETARY FILLER.

Flexitallic’s SIGMA® ONE was developed to meet the industry’s most critical chemical service applications. Research & Development efforts extended over two years in order to provide the market with a PTFE-based sealing material that was truly ideal for service.

- Flexitallic’s proprietary manufacturing process allows for high-performance in every direction (biaxial).

- The formula incorporates PTFE & a proprietary filler, which are both well-known for their exceptional chemical resistance.

- Reduced risk of misapplication and inventory consolidation are a result of SIGMA® One’s excellent chemical compatibility.

- High compressibility provides easier installation and lower load to seal, minimizing the likelihood of equipment damage.

- SIGMA® One provides superior creep & cold flow resistance, increased sealability, decreased emissions & peace-of-mind.

- SIGMA® One’s biaxially-orientation makes it the ideal solution for applications with elevated mechanical requirements.

UNIVERSAL CHEMICAL COMPATIBILITY

Until now, chemical manufacturing facilities have been required to utilize a variety

of conventional-filled PTFE materials to cover the chemical range in its entirety.

Thus, increasing the likelihood of gasket misapplication.

- PTFE is commonly used for sealing within chemical service applications.

- 100% Pure PTFE provides excellent chemical compatibility, but does have its drawbacks.

- Pure PTFE is not stable under heat & pressure, which is known as “creep.” Excessive “creep” results in the loss of load on the gasket, and therefore increases the likelihood of leakage.

- In order to minimize creep, fillers are commonly added to PTFE during the manufacturing process.

- Fillers help to stabilize the gasket, but each has its own chemical compatibility limits and related trade-offs.

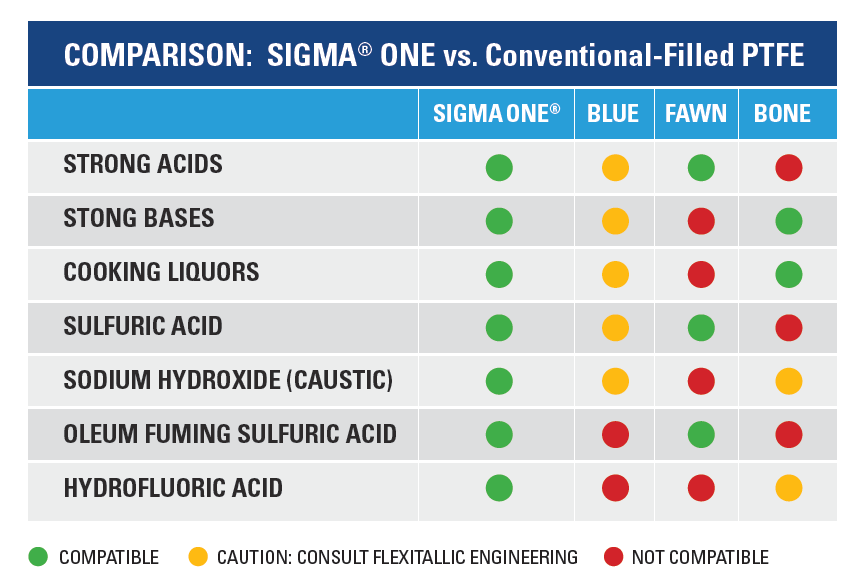

- The most common fillers are glass spheres (blue), silica (fawn), and barium sulfate (bone or off-white).

- Many companies must utilize a wide variety of materials to properly seal the assortment of chemical service applications.

- Companies that utilize a variety of PTFE sealing materials are more at risk of misapplication, which can negatively impact safety, reliability, and up-time.

When compared to other conventional-filled PTFE (glass spheres, silica, barium sulfate) sheet sealing materials, SIGMA® ONE’s near universal chemical compatibility minimizes the risks associated with gasket misapplication.