Safer sealing solutions for the Oil & Gas industry.

The oil and gas industry can be broken down into upstream and downstream operations.

The challenges faced by organisations working in the upstream oil and gas industry depend on the location of the crude oil and natural gas. Upstream operations are primarily concerned with extraction and transportation; offshore upstream operations have the added challenge of working within a hostile subsea environment.

The challenges of downstream operations are focused on subsequent processing of crude fossil fuels.

We realise that time is definitely money when it comes to the oil and gas industry and gaskets are a small, but critical, component. Failed flanged joints can lead to health and safety risks, environmental damage and significant financial loss for an organisation. The stakes are even higher for upstream operations, where high pressure and the risk of galvanic corrosion place additional demands on flange joints.

At every stage we help you to reduce the risk of downtime. We’ll advise on the most appropriate sealing material for each application and, if required, we’ll train your engineers on correct installation and maintenance through our dedicated training division.

Featured products for Oil & Gas

Download our Oil & Gas brochure

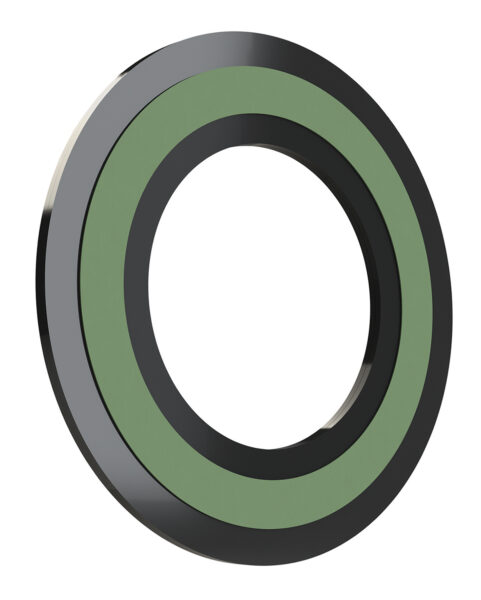

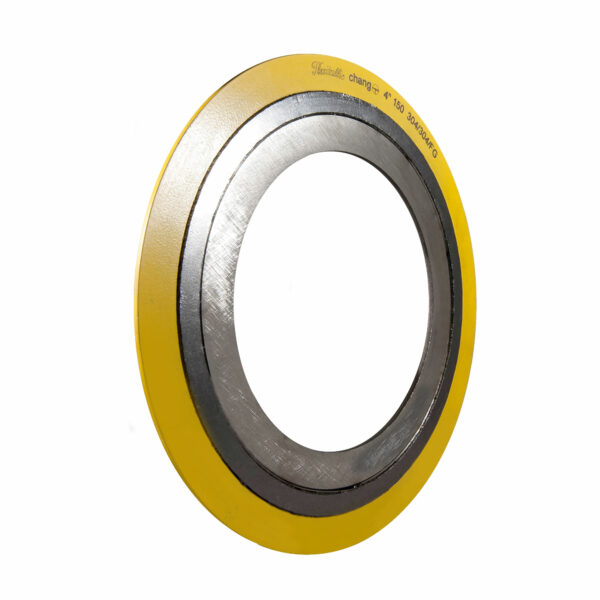

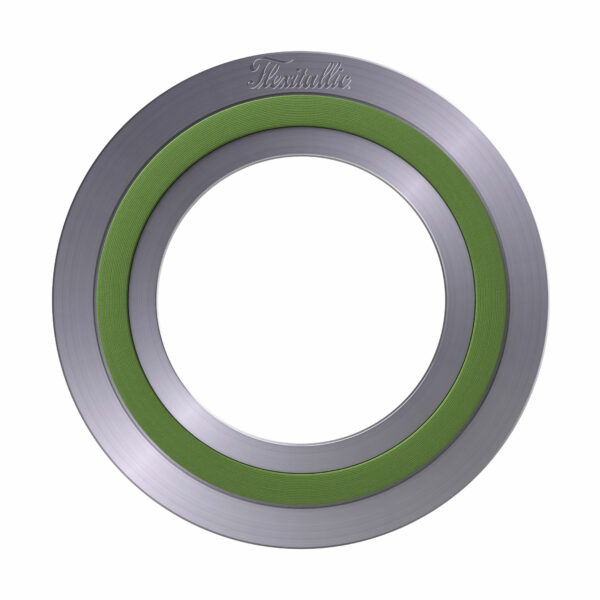

More than a century ago we developed the spiral wound gasket. Today it remains one of the most effective sealing solutions for the oil and gas extraction industry. Yet we’ve continued to push the boundaries. More recently we’ve developed our unique Corriculite™ material, designed to mitigate flange face corrosion.

- Stephen Bond, VP of Research and Development, Flexitallic Group