Industrial sealing solutions for Aggressive Chemicals

Aggressive chemicals can present significant sealing challenges even at low temperatures and pressures. Chemicals can degrade the sealing element, pipe bore, and flange face, eventually compromising joint integrity. The consequences of chemical leaks can be severe, particularly when dealing with toxic, corrosive or flammable media.

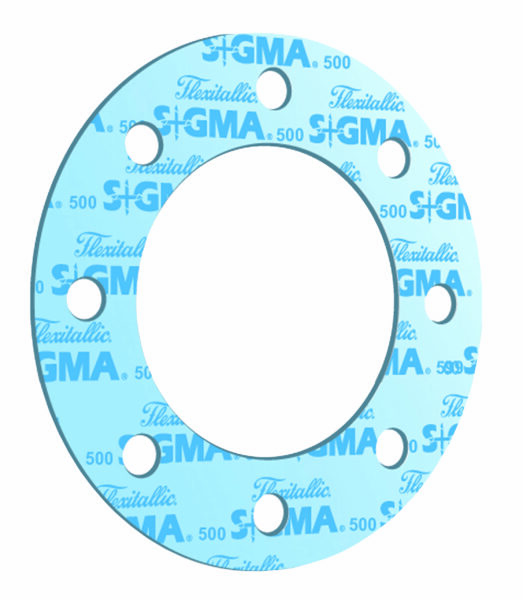

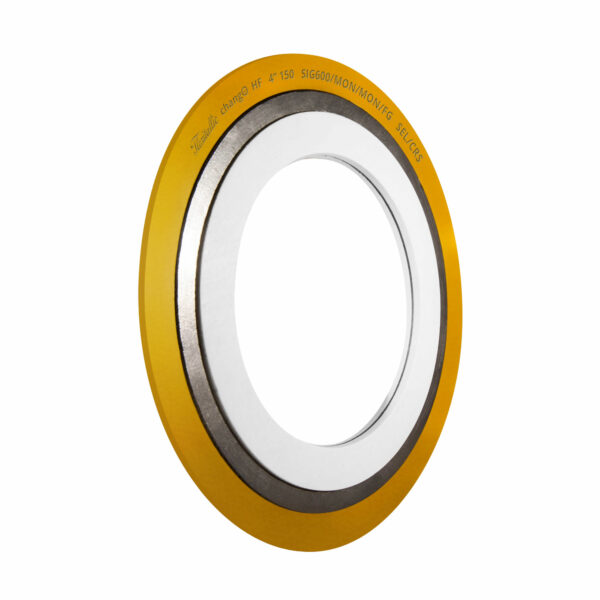

To minimise seal degradation, gasket materials must be chemically compatible, and capable of performing at the specified temperature, pressure and chemical concentration. For applications where use of conventional metalagy is not possible, the use of glass, plastic, or lined pipework is commonplace. This can place additional demands on the seal, for instance, assembly loads may be limited and smooth sealing faces can give rise to enhance gasket creep and blow out failure.

To find out more about Gaskets/Seals for Chemical Service and Aggressive Chemicals see our recommended products below, or contact us to speak to one of our sealing experts.

Featured products for Aggressive Chemicals

Download our Aggressive Chemicals brochure

As a seasoned Sealing Applications Engineer some of our most demanding sealing challenges often involve Aggressive chemicals. Coming up with the best solution can require an appreciation of not just the application conditions; temperature, pressure and media but the subtle interplay of all three with regard to the most appropriate gasket design.

- Dene Halkyard, Technical Director, Flexitallic UK Ltd