Fire-safe sealing solutions for the Petrochemical industry.

Risk of fire is a major hazard for the petrochemical industry, due to the highly flammable substances involved in production. The risks are further increased with the high temperatures and pressures required for the process of cracking petroleum into hydrocarbon-based products. In such environments, accidental leaks from ineffective or degraded seals can have devastating consequences.

Considering that some petrochemical plants have potentially thousands of joints, it’s vital that you can trust the reliability and performance of flange seals. Our fire-safe Thermiculite® sealing materials meet API 6FB standard, the only recognised fire-safe test for gaskets. As well as the risk of fire from materials leaking out of a pipe joint, there’s also the risk of an external fire igniting materials within the joint and making the situation worse. Our fire-safe gaskets have all passed stringent tests, so you can be confident that they’ll maintain their integrity.

Featured products for Petrochemical

Download our Petrochemical brochure

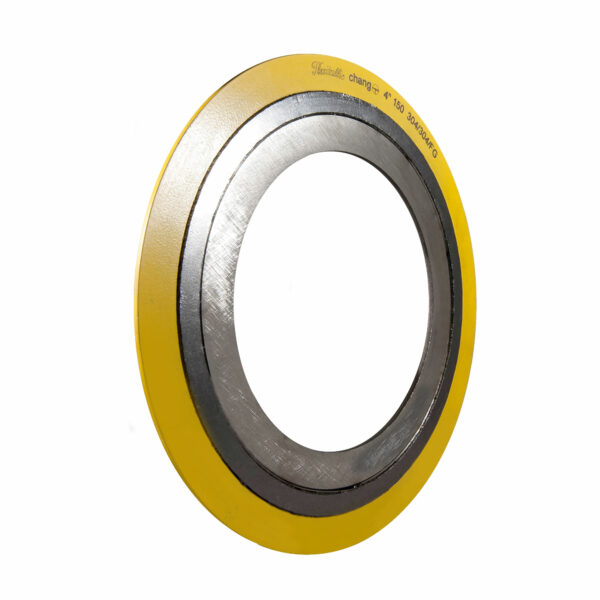

Flexitallic Change, and Change-CR have been the first choice for solving the most challenging applications in Petrochemical industries around the world. Change type gaskets are capable of sealing highly cyclic conditions where other traditional type gaskets, such as Kammprofiles, are not able to provide a leak free joint. Change-CR type gaskets can seal highly cyclic applications while protecting the flange faces from corrosive chemicals involved.

- Vinay Tripurana, Applications Engineering Manager, Flexitallic UK Ltd