Long-lasting solutions during Thermal Cycling

During thermal cycling and heat exchange processes, pipes and joints undergo constant heating and cooling. The resulting expansion and contraction impact the bolted joints and, unless the sealing materials can react effectively to the constant temperature changes, the joint will become compromised. This can lead to leaks, unplanned downtime and reduced business performance.

To maintain seal integrity, it is recommended to select the materials for flange, gasket and bolts with the same or close coefficient of thermal expansion. This gives uniform contraction and expansion throughout the joint and avoids the loss of bolt load due to the large differential thermal expansion. Where possible, the same or similar materials should be used for mating flanges and gaskets to minimize the risk of galvanic corrosion or oxidation, especially when the temperatures are high.

Another issue is that over time the constant heating and cooling causes traditional gaskets to lose their elasticity, and eventually the seal will fail. We’ve created a range of gaskets which are proven to maintain resilience even during extreme heat exchange or thermal cycling operations.

Featured products for Thermal Cycling

Download our Thermal Cycling brochure

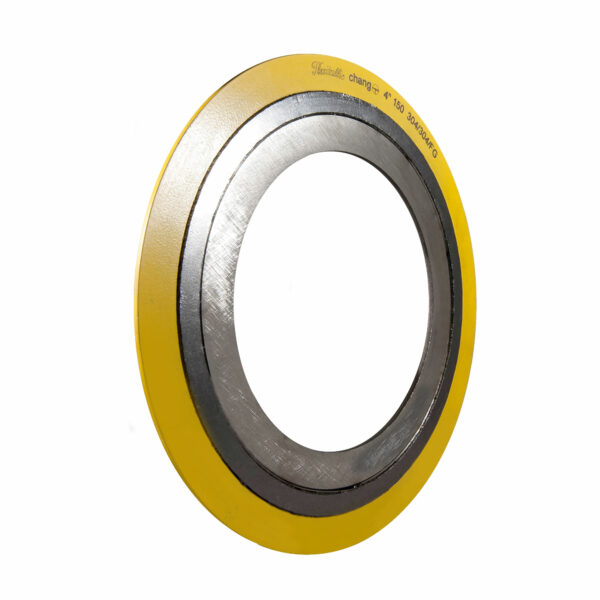

Extreme thermal cycling leads to flanges expanding and contracting, placing the gasket under varying stress. While traditional gaskets work effectively for applications where the temperature differential is relatively small, more extreme temperature changes demand a more robust yet dynamic gasket, which is where our innovative Change™ technology comes into its own. The Change™ gasket, with its superior recovery acts like a spring – it compresses and stores elastic energy when the flanges expand during heat up, and expands to maintain the gasket stress when the flanges cool down.

- Yi Li, Product R&D Engineer, Flexitallic Group