Sealing solutions that meet the demands of Power Generation

Superheated steam that is used to drive turbines in power stations brings its own challenges. Gaskets and flange joints must maintain their integrity at temperatures reaching 600oC/1112°F, while the increased risk of oxidation can lead to galvanic corrosion and premature seal degradation.

If undetected, this can result in leaks or even blow-outs. As well as the obvious health and safety risks, the resulting unplanned shutdown or outage can cost an organisation literally hundreds of thousands of pounds each day.

By advising on the selection and correct installation of appropriate sealing technology, we’ll help you to minimise the risk of gasket degradation and increase operation time between scheduled maintenance, leading to significant cost savings. And, when you require replacement parts, our quick turnaround on standard or bespoke gaskets will make sure your plant is up and running as fast as possible.

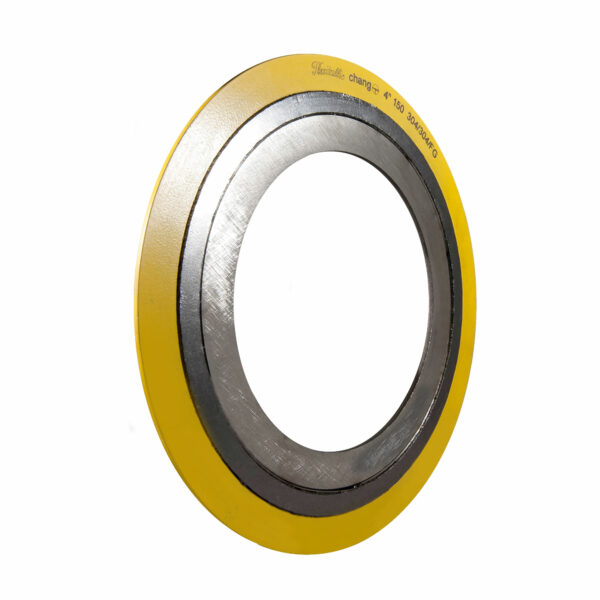

Featured products for Power Generation

Download our Power Generation brochure

Time is certainly money in the world of power generation. Investing in high-performance, long-lasting gaskets will lead to long-term savings. Our experts can match our products to your needs and manufacture gaskets to your exact specification. The fact that we can turn orders round extremely quickly, is also a huge benefit for our customers.

- Gary Milne, Academy Director, The Academy of Joint Integrity