Thermiculite® 870 is used in solid oxide fuel cells (SOFC) where the primary sealing material requirements are very low stress sealing.

As with Thermiculite 866 the material provides electrical isolation, is non-contaminating and can accommodate complex gasket geometry.

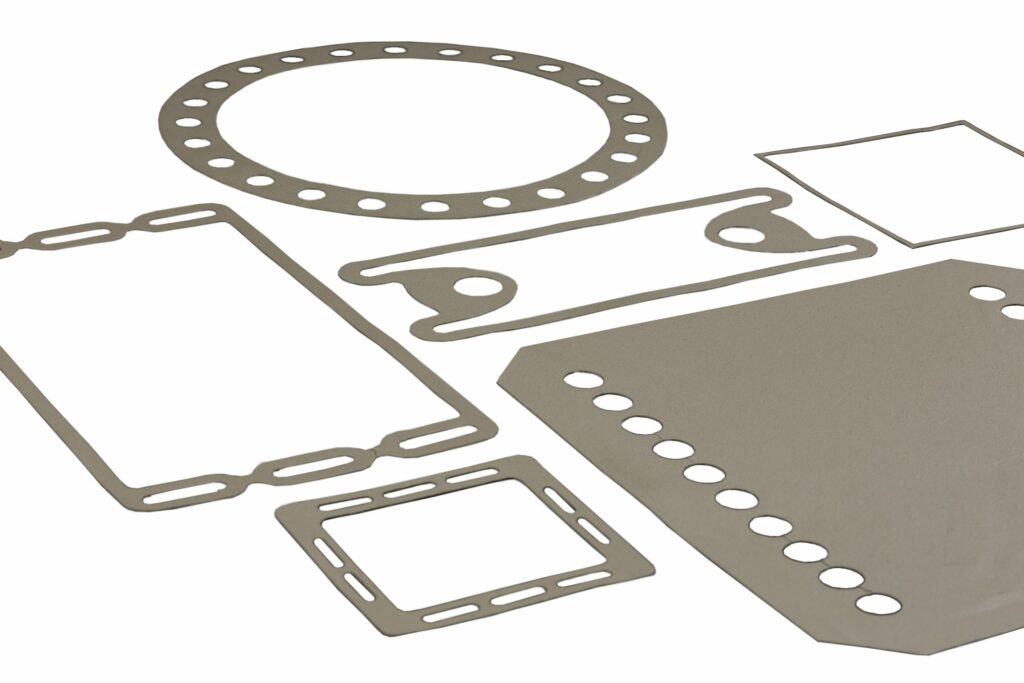

It can be supplied in a range of thicknesses from (0.3mm to 1.0mm) in cut seals to suit your stack design and can be provided with additional glass or anti-stick coating to further enhance its properties.

TH870 utilizes the unique properties of Thermiculite® technology, developed by Flexitallic based upon the use of chemically exfoliated vermiculite, to produce a range of high-performance, high-temperature resistant, electrically insulating, patented sealing materials.

The minimum gasket stress requirement of Thermiculite® 866 is not always achievable, especially given stack materials (e.g. ceramics) and constructions. Thermiculite 870 was formulated to seal at a very low gaskets stresses whilst still maintaining the capabilities of 866.

- Greater level of compressibility at low loads, making it suitable for a wider range of SOFC/SOE applications

- Improved sealing at low loads and good stress retention

- Ability to compensate for small manufacturing tolerances elsewhere in the unit cell