Safer sealing solutions for the Agrichemical industry.

Agrochemical production delivers a host of challenging environments. Aggressive chemicals, such as ammonia and nitric acid, must be contained. Temperatures can exceed 1000oC/1832°F, creating a highly oxidized environment, while pressures can rise to 2900psi/200 bar. Thermal cycling, experienced during routine maintenance, further increases demand on equipment.

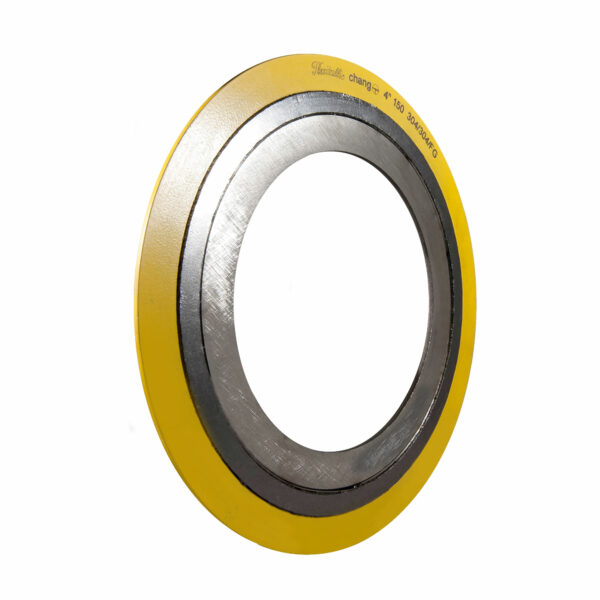

For such a challenging application, one small component can make the biggest difference. Selecting the right gasket material can minimize downtime, maintain safety and maximize the efficiency of plant operations. Flexitallic has developed a wide portfolio of gasket products specifically for the complex environment present in ammonia/nitric acid production. Core to the range are two products; Thermiculite® and ChangeTM.

Featured products for Agrichemical

Download our Agrichemical brochure

Following the ban on the use of asbestos based gaskets in many developed countries, flexible graphite material became the main choice for replacing asbestos. The use of graphite based gaskets in the agrochemical industry (mainly fertilizer manufacturing plants) were followed by many failures due to the lack of resistance of graphite when exposed to oxidizing media such as nitrous gases and nitric acid used in this industry. Today, many fertilizing plants have converted to Thermiculite based gaskets which have resolved the issues raised by graphite in this industry.

- Jamal Jamalyaria, Director of Engineering, Flexitallic